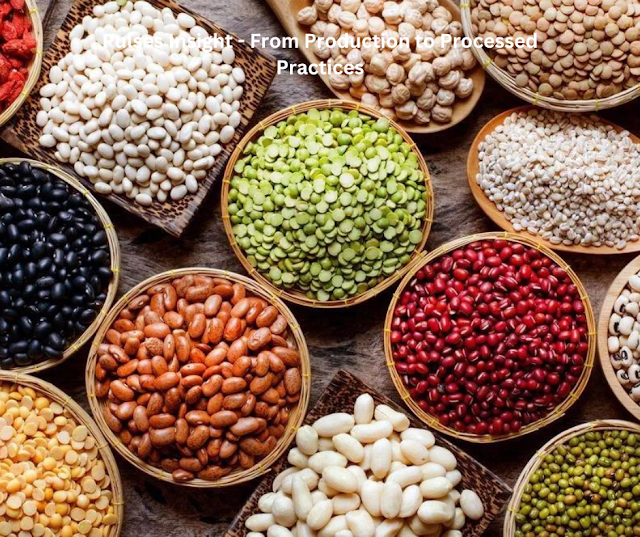

Pulses Insight - From Production to Processed Practices

Toor dal is called by another name that is pigeon peas. It has a high protein content which is equal to three times of the other cereals. Moreover, they are considered the best source of protein for the vegetarian population especially, in India. India is the biggest consumer of toor dal, with the report of large vegetarian population existence. Additionally, this is one of the top and largest pulses production countries, thereby many pulses supplier in India is gaining momentum in the market.

India has accounted for a large vegetarian

population which leads to rising pulses consumption, which is contributing

further to the growth of the economy. Pigeon peas are locally called toor dal

and moreover, called by different names in different parts of the country.

Additionally, for instance, Arhar dal in Hindi, Adhaki in Sanskrit, and Tur dal

in Bengali. These are great sources of proteins and fibers.

Toor Dal Overview

Toor dal is called by the other name that is

pigeon peas. It has high protein content and is considered a great source for

the vegetarian population. India is the largest pulses producer and consumer,

in addition to this, it has reported a large existence of vegetarian

population. Hence, pulses are India’s staple food.

Harvesting Practices

After a long time of four to five months with

good hard work and maintaining some specific measures to the products, the

pulses then are harvested. Afterward, these are transferred to the

manufacturing units and warehouses to store efficiently using a well-equipped

storage system. In order to maintain the pulse quality.

Supply Chain Management

Supply chain processes from farmers to consumers

way cost considerably expensive due to the impact of various factors -

- Shortage of delivery man, off-road driving, and hiked

diesel & petrol prices.

- And most importantly, the supply chain includes different providers starting from farmers to traders to wholesalers to semi-wholesalers to retailers to consumers, at each stage price gets added as per their desire and delivered to consumers at a set yet little expensive price. Many pulse suppliers in India are supposed to cross all the stages.

Online delivery of the product is alleviating considerably owing to the increased popularity of online delivery with convenience. Additionally, this is one of the popular pulses, which has created a high demand across the country, apart from Asia Pacific regions, in the Middle Eastern, and African regions it has created popularity. In addition to this, it facilitates a strong relationship between customers and sellers, as they provide numerous facilities regarding product exchange, refund policy, and easy product replacement. In addition to this, this is one of the best solutions that are proven easy and convenient for people who are opting for online purchases.

With respect to this, the entire process and growth of the market are dependent on several factors driving the growth of the market at a considerable rate. Moreover, this refers to the addition of the respective costs at each stage that eventually leads to an increasing the product’s cost. The most effective

It includes the entire process starting from the product’s selection to the product’s delivery with effective packaging solutions. Also, this facilitates the consumers to avail products in a cost-effective manner.

2. The Production Process Involves Various Methods That Are Mentioned Below

Precleaning, oiling, drying & cooling,

de-husking, splitting & grading, sorting, polishing, and packaging. Toor

dal is highly consumed among the other dal varieties. Thereby, toor dal supplier in India is rising coupled with the rising export practices

resulting in an increase in the urad dal exporters.

Precleaning

Pre-cleaning and dumping are the primary steps taken to remove the dirt and dust particles before it is processed. After removing all the dust particles, they are then transferred to the large tanks to make pulses free from all the solid small stones.

In addition to this, all the pulses after

being cleaned are packed and delivered to wholesalers and then further to the

retailers.

Oiling

After being cleaned, pulses are now oiled to

make them smooth finish appearance. Pigeon pulses are oiled that absorb the

hard and thick waste that remains after the first step. Additionally, this

process removes the hard waste or dirt, and then later on, the entire used oil

is dumped into the tank to collect the used oil to proceed with a further

step.

Drying and Cooling

Once pulses have oiled they are now transferred through the dryer and heated for around 4 to 5 hours. The duration depends on the moisture content absorbed by seeds. Then the filled dryer is transferred to the cooling chambers according to the set moisture.

Splitting and Grading

Now the splitting process is done after the

drying of pulses. Toor dal is now split into two halves through a grinding

machine that will divide the grains later on, according to their sizes.

Sorting Based Colors

Once the grinding process is completed, then the

Toor dal is transferred into a color sorter machine where the toor dal is

divided as per the color context. In this process, the pulses segregation

process is done on the basis of the color, where green colored toor dal is

divided and yellow colored dal. And all the present dust and dirt get removed

by the extreme air pressure. All the green colored and yellow colored toor dal

are segregated and sorted based on the colors and sizes.

Polishing Practice

In the polishing process, toor dal is now ready

to be moved to the polishing process. Dal polishing is performed as per

consumer preferences. The type of quality they require has been determined

through this method and then passed for the packaging process.

Packaging

Lastly, toor dal is now moved for the packaging

process, after being processed completely. After being packed they are sold to

wholesalers and eventually to consumers. Pulses manufacturers perform the

entire process before selling the pulses to pulses suppliers.